Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai

Test instrument for scrubbing resistance of architectural coatings to determine the scrubbing resistance of coatings

Introduction to the

The diversified design of scrubbing tester is suitable for various abrasion resistance and wet scrubbing tests. Usually used in interior wall paint, floor tile, shower room and furniture surface scrub test. Coated or uncoated surfaces need to be tested for scrubbing resistance with a brush, sponge, dishcloth, sandpaper, or other method. A wet scrub can be used to test the resistance to friction by adding a friction agent or cleaner.

The test principle of

1. Drive the friction head reciprocating motion under the drive of the motor. At the same time, according to different standard test requirements, adjust the movement rate and travel distance of the instrument;

2. Different rubbing heads are required for different standards, including polyurethane sponge and pig MAO brush. By replacing the friction head, the requirements of different standards can be achieved and different forces can be applied.

Test standard

This horizontal combustion tester meets, but is not limited to, the following standards:

Paints and varnishes: ISO 11998;

Interior wall coatings: ASTM D3450, ASTM D4213, ASTM D4828; ASTM D2486

Floor wax: ASTM D1792, ASTM D3206, ASTM D3207.

Technical specifications

Movement frequency: 37±1;

Stroke: > 300 mm;

Instrument size: W368mm×D216mm×H356mm;

Timing: accurate to 0.1s;

Weight: 15 kg

Power supply: 220V, 50Hz;

Selected listing

Scrub brush kits shall be customized according to different tester requirements and standards, subject to actual orders:

1 main engine;

1 pallet;

2 fastening clips;

1 glass liner;

1 copper strip (equipped according to contract and standard);

1 set of brushes (equipped according to the contract and standard) general type, 1.5×3.5in(38.12×88.9mm); Can be placed in brush base 5074;

1 power cord;

Composition and use of instrument

The instrument is mainly composed of two parts: the main engine case and the scrubbing brush.

The instrument (with a horizontal leg) is fitted with a cover plate with a steel groove on which a sample holding device is placed. Two brushes, sponges or scrubbing pads are fixed to the bracket and cantilever. Linear forward and backward movement is obtained through an electric motor and through an eccentric wheel and a stay wire device. A pre-set counter with 8 digits is installed to record the number of cycles (forward and backward movement), and the power to clean is accurately provided by an adjustable peristaltic pump. The control interface can adjust the operation parameters: scrubbing cycle number, scrubbing brush movement frequency, etc.

steps

Instrument to

The test instrument shall be installed in an appropriate position free from debris and obvious dust, and the scrubbing test instrument shall be placed at an appropriate height for test personnel to operate;

Plug in and turn on the side power switch. Applicable to ordinary power supply: 220V, 50Hz;

Use the bubble level to flatten the instrument, adjust the four feet at the bottom of the instrument until the surface of the instrument is level, so that the instrument is stable and without shaking;

Put the bearing plate, and put all sides of the bearing plate into the indentation mark on the top of the instrument.

The instrument is equipped with two clamping spring clips for holding samples. It can be lifted or lowered by inserting it into the hole at the back end. When pressed, it can compress the sample to be blessed.

Sample preparation and testing

Different materials correspond to different test standards, and their preparation methods and quantities are not the same. The sample preparation should be carried out according to different test standards

Take ASTM D 2486 for example.

Test method A

Stir the test coating thoroughly to remove all bubbles and particles. For each coating you need to pull out 3 coatings. Scrape the coating off the black plastic panel using the same 0.18mm gap film coating model. The application time from one end to the other is about 3~4s, preventing the formation of bubbles or cavities in the film. At 23±2℃ and 50±5% relative humidity, dry in the air horizontally for 7 days.

Soak the brush in water. Place the sample plate on the load plate of the scrub tester. Make sure the copper strip gasket is smooth and free of burrs and is placed perpendicular to the brush path. Gently wipe the sample board and place it over the copper strip, paint up. Ensure that there are no defects in the sample film above the copper sheet and that the test area is horizontal. Place positioning frame on plate and clamp tightly.

At the beginning of the test, confirm that the brush has been pretreated for 400 cycles. Take out the brush and toss out the excess water. Apply about 10g of evenly stirred scrubbing medium to the sample. Place the brush at one end of the path. Wet the panel with 5mL of water in the brush path.

Start testing. After 400 cycles, if no failure occurs, remove the brush (do not rinse), add 10 g of stirring scrubbing medium again, add 5 mL of water to the brush path, and continue scrubbing.

Record the number of cycles when a continuous thin wire is scrubbed on the copper strip at a width of 12.7mm. If necessary, stop the machine and wipe the gasket area to determine if the end point is reached.

Test both coats. If the two results differ by more than 30% of the average, test the third coating. Discard one of the three results with too large a deviation and average the remaining results.

Test method B

Fully stir the test coating and reference coating to remove all bubbles and particles. Pull out two coats side by side, following the procedure described above. Prepare three sets of sample plates for each test paint (including reference paint). The coating should be pulled out as far as possible at the same time. The coating portion should be in the middle of the sample. Dry for 7 days under standard conditions.

Place the sample plate and 2 copper bars in the same way as in method A and fix them.

At the beginning of the test, confirm that the brush has been pretreated for 400 cycles. Take out the brush and toss out the excess water. Apply about 10g of evenly stirred scrubbing medium to the sample. Place the brush at one end of the path. Wet the panel with 5mL of water in the brush path. It is recommended to change the position of test coating and reference coating in two groups of sample plates to test. That is to say, one sample plate on the right has a reference coating, and the second sample plate on the left has a reference coating.

Record the number of cycles of continuous fine lines (scrub marks) appearing above the test coating and the reference coating, respectively. If necessary, stop and wipe the strip area to determine if the test endpoint has been reached.

Test both coats. If the two results differ by more than 30% of the average, test the third coating. Discard one of the three results with too large a deviation and average the remaining results.

Lab report

Report the following information:

When test method A is used, report the average scrub failure.

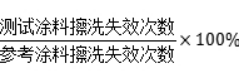

When using test method B, the following percentages are reported:

If:

Results BBB 0 100%, the test coating has better scrubbing resistance than the reference coating.

If:

Results <100%, the test coating has worse scrubbing resistance than the reference coating.

Method used (test method A or test method B).

Use the reference coating if using test method B.

Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai