Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai

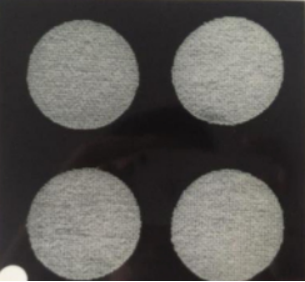

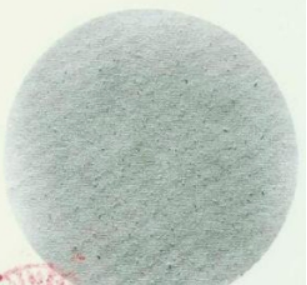

It is applicable to all pilling hook wire test rating standards. The rating results are obtained by comparing the sample with the standard chart card under the established light source. Applicable types: martindale pilling test,ICI pilling test,ICI hook test, random roll pilling test, circular track pilling test

Compliance :BS 5811 EN ISO 129454/1/2/3

ASTM 3512 ASTM D 4970

ASTM D 5362 IWSTM152

BS 5811;

BS EN ISO 12945;

ASTM D 3512;

(4) ASTM D 4970;

ASTM D 5362;

6, IWSTM 152;

7, Next TM 19/26;

Test standard

There are many testing standards for foreign textile fuzz and pilling, the common standards are: American test and materials association standard ASTM, Japanese industrial standard, German standard DIN, British standard BS, international standard ISO and so on.

Test standards and conditions

At present, there are three main standards for testing the pilling and fuzz of textiles in China:

GB/T4802.3 -- 1997 "test method for fabric pilling -- pilling box method", test conditions, no pressure;

(2) GB/T4802.2 -- 1997 test method for fabric pilling -- martindale method, test conditions, under slight pressure;

(3) GB/T4802.1 -- 1997 test method of fabric pilling -- pilling method of circular track, test conditions, under slight pressure.

Testing instruments

Pilling test instruments abroad mainly fall into the following three categories:

1) pilling box type: equivalent to domestic pilling box type;

2) flip: the fabric rolls in the cylinder, causing pilling and pilling without regular friction;

3) martindale type: it has two functions of testing friction and pilling.

For textile export enterprises, facing different standards of trading countries, it is more difficult to test the pilling problem of textile products. From the perspective of the testing methods of most textile importing countries, they are generally limited to the turning over method and martindale method. The latter method is mainly used for textiles with high requirements for fuzzing and pilling performance, because this method is closer to the process of human consumption. With the internationalization of textile market, textile enterprises should learn to adapt to many foreign testing standards, including textile testing standards for pilling.

Iv. Testing method of pilling and fuzz

The anti-fuzz and pilling performance of the fabric can be tested by various testing instruments, such as rolling box type, brush grinding type, etc. The analysis methods of test results are as follows:

(1) counting method: the number of pilling in the specified area;

(2) measurement method: that is to weigh the weight of the ball on the fabric and fall;

(3) sample comparison method: the fabric after pilling is compared with the standard sample to determine the pilling degree of the sample. The pilling degree is divided into five levels. The smaller the level is, the more severe the pilling is, and the larger the level is, the better the anti-pilling performance is.

(4) coordinate representation: use the vertical coordinate to represent the pilling number and the horizontal coordinate to represent the pilling curve of friction time to analyze the pilling degree and the pilling formation and shedding rate.

The results show that different instruments and testing methods are used to determine pilling and pilling, and different evaluation results will be obtained. The testing methods and instruments of wool and pilling of textiles at home and abroad are introduced below.

Testing method of fuzz and pilling -- domestic textile fuzz and pilling test

Five, pilling process

(1), fluff: fabric by the external repeated friction, when the friction force is greater than the fiber strength or friction between the fibers or binding force, fiber ends are pulled out of the formation of nap, fabric surface formation of nap cloth surface luster;

(2) entanglement into a ball: when pulled out of the nap exposed a certain length, a certain distance of the nap due to kneading, friction repeated extension and shrinkage and tangle into a ball, the ball formed by the fixed fiber and fabric surface connected;

(3), off the ball: in the process of friction, washing, wearing and cleaning, continuous force on the fabric, connecting the ball of fiber repeatedly stretching and bending fracture, so that the ball off from the cloth.

Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai