Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai

Wear-resistance and color fastness of textile surface are important indexes to measure the serviceability and durability of textile. Wear-resistance tester is an instrument to test the wear-resistance and color fastness of textile surface structure that is swabbed under different pressure.

Schauber wear tester is used to test the appearance change of fabric samples after friction or wear test. It is mostly used to test automobile interior materials. During the test, the abrasion resistance of the rotating sample was measured by applying friction to the tangential direction of the rotating sample by friction components.

According to the standard

The design of this instrument conforms to DIN53863.2, GME Standard 60345, GMW Standard 3283, VW/Audi zentral-norm PV 3908 and other standards.

The basic principle of

The circular sample is mounted on the rotating test head. The sample is rubbed against the friction material (sandpaper) at a certain speed, pressure and number of rotations along the clockwise and counterclockwise directions by means of rotary wear. The friction material keeps a linear contact with the sample, so it can produce a friction effect in a tangent direction. Change rotation direction 100 times per friction (optional). Test results are evaluated by quality loss and the generation of holes.

Technical parameters:

Rotation speed: 75R/min;

Cone Angle is 166 °;

Tilt Angle of test head bracket is 7°;

Sample size: 100cm2;

Test area: 50cm2;

The arch height of the sample is adjustable, with measuring accessories, measuring range is 0 ~ 10mm;

Sample downforce: 0.5n ~ 25N adjustable,

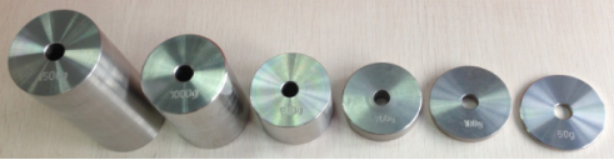

One set of load weights: 50g, 100g, 250g, 500g, 1000g, 1500g;

Overall dimension: 325×565×560mm;

Weight: 35 kg;

Power supply: 220V, 50/60hz;

Power: 130W.

Instruments and equipment

Instrument structure drawing

Instrument attachment drawing

Configuration weights

(1 weight of 1500, 1000, 500, 250, 100 and 50g each)

Instrument function introduction

The apparatus includes a chuck and a clamping device with a support for scrubbing the sample (reference material), a pressure plate for fixing the friction (opposite material) and a moving device. The clamping device is equipped with a conical chuck (opening Angle 166°) with working sample support, which forms a 7° inclination Angle with the vertical line and rotates along the vertical line and its own axis, so the clamping device also generates rotary motion. Corresponding to the working principle of the instrument, the envelop line with a length of about 40mm on the surface of the conical chuck is always in contact with the flat friction material (sandpaper) surface, so that the sample with an area of 50cm2 and each position of the friction material surface are subjected to the same degree of friction in a circular manner.

The structure of the specimen clamping device for a ring clamp, including an external ring is used for clamping the friction of the sample, by a friction can tighten the locking ring specimen clamping in the interval of frustum cone ring, clamping device also includes a can tighten the collet, used to adjust the sample on the surface of the conical positioning height. The removable clamping device is firmly fixed on the driven gasket, which rotates electrically driven at a speed of (75±5)r/min.

After every 100 times (instrument can be set) scrubbing rotation, under the action of automatic locking device, the transmission device stops running. Change the direction of rotation by switching. Display the number of rotation of single direction friction by single counter. Total friction rotation times are displayed by the accumulative counting device.

The platen design has two fastening plates and a clamping screw for clamping sandpaper as a friction material. The platen is supported by one end of a double arm lever in a frictionless position as far as possible and is balanced by a balancing piece on the other end of the lever arm. The pressing force of friction material can be adjusted between 0.5N and 25N by loading weight.

Operation method

The sample treated by temperature and humidity is installed on the sample fixture with the accessories configured with the instrument to form a rotating test head, as shown in FIG. 10 and FIG. 11. And use arch height test device to adjust the protruding height of test head according to relevant standards or other specified requirements, generally 5 ~ 8mm

The test head mounted on the sample is installed on the test head mounting plate on the instrument working table. The test head is installed and tightened by matching the positioning pin on the mounting plate with the positioning hole below the test head.

Use the friction fixture located on the pressure plate of the instrument to install the friction sandpaper on the lower surface of the pressure plate. The locking fixture ensures that the sandpaper is clamped and installed smoothly.

Pull the lifting lock of the pressure plate on the right side of the pressure plate outwardly, and lower the pressure plate to make the sandpaper contact with the sample surface on the test head.

Weights of corresponding weight (the instrument is equipped with one standard weight of 1500, 1000, 500, 250, 100 and 50g each) are installed on the weight shaft above the pressure plate, so that they exert a certain pressure on the friction of the sample. According to the size of the sample weight per unit area, the pressure value to be applied is selected.

Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai