Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai

Introduction of multi-function reciprocating abrasion tester

The multi-function reciprocating abrasion tester is used to test the resistance to scratch and abrasion of coatings, plastics, decorative fabrics, automobile interiors, velvet fabrics, etc. LCD control and display the test process, can be set according to user requirements reciprocating wear times, motion travel, reciprocating speed and other parameters. Unique friction arm design, the realization of different friction head replacement. The implementation of precise pressure control according to lever balance principle. Fully meet the different requirements of different standards for friction form, friction head, pressure, etc.

1 test principle

The test sample is held on a horizontal bench and worn down as it moves horizontally with the specified abrasives and loads. The other end of the test arm is equipped with a weight to maintain the balance of the test arm to ensure the accuracy of the sample surface load. abrasive

And the load rack height is adjustable to suit the test of samples of different heights.

2 test standards

ASTM F2496, ISO 1518-1, ISO 1518-2, GME 60248, D42 1775, etc

The instrument consists of the following parts: additional weight, friction head, balance bar, fixing knob, locking knob, and balance weight; The LCD panel; Power switch; Emergency stop button.

Additional weights: different additional weights are equipped according to different standards and customer requirements. After adjusting and balancing, the weight of additional weights is the weight pressed on the sample.

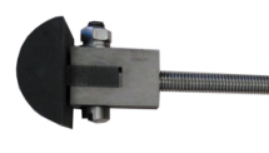

Friction head: according to different standards and customer requirements, there are a variety of friction head can be replaced. The instrument is equipped with friction head and its fixture as follows: for the grinding head of D42 1775, sandpaper shall be attached to the arc surface of the grinding head during use. For rubber mounting grinding head and sleeve, the sleeve shall be disassembled in use, the green grinding head shall be placed in the middle of the sleeve, and then the top wire shall be used to highlight and tighten it, and the grinding head shall be exposed to the surface of the sleeve 0.1in.

1. D42 1775 standard grinding head

Grinding head 2. Rubber grinding head and stainless steel mounting jacket

Fixing knob: loosen the fixing knob. If the balance weight and the weight of the friction head cannot reach the balance, the balance bar will tilt. On the contrary, if the fixed knob is locked, the current position can be locked even if the balance bar is not balanced.

Locking knob: after tightening, the front and rear ratio of the balance bar can be locked.

Balance bar: to measure whether the lever balance and support connection.

Balance weight: according to the principle of lever balance, move the front and rear position of the balance weight to balance with the friction head. The pressure applied to the weights is the pressure applied to the actual fabric.

LCD: it has the functions of setting test parameters, displaying and controlling the test process.

Power switch: start or turn off the instrument.

Emergency stop button: in case of emergency, press the emergency stop button to turn off the instrument.

4. Technical specifications

Travel range: 6-150mm adjustable

Speed range: 1-100 reciprocating /min stepless adjustable

LCD control, can set the speed, the number of reciprocating motion and other parameters

LCD displays and controls the test status in real time

Two station design, saving time of test

Can meet various standard requirements, according to the needs of users with weights and friction head

Weight: 48.5 kg

Size: 532 * 471 * 630 (W * D * H)

Power supply: 220V, 50HZ, 3A

5. Optional

Host 1

Test software set 1

2 sets of test arm kits

6 weights (1N,2N, 3.5n,5N,10N,24N)

2 grinding heads of D42 1775 (R18, 40mm long)

2 grinding heads of cs-10

H-18 grinding head 2

2 sets of sample fixing frame

1 the brush

1 pack (20 pieces)

1 power cord

1 manual

6. Comparison table of relevant standards

Project standard

ASTM F2496ISO 1518-1iso 1518-2gme 60248D42 1775

Speed (mm/s)/s35 + 5 mm / 6 mm s10mm/s50mm/s20mm/s

Single-line distance ≥100mm≥40mm100mm plastic ≥25mm, fabric =50±5mm40mm

Speed (reciprocating /min)≤1.8 reciprocating /min≤30 reciprocating /min3 reciprocating /min plastic ≤60 reciprocating /min, fabric =30 reciprocating /min15 reciprocating /min

Friction head friction pen: cylindrical, outside diameter 7.21mm

Friction ring: U type, outside diameter of 1.6mm

Rockwell hardness of the two is 56-58 friction pen, nib A/B/C/D four kinds

A: hard hemispherical metal, radius (0.5±0.01)mm

B: hard hemispherical metal, radius (0.25±0.01)mm

C: semispherical artificial ruby, radius (0.5±0.01)mm

D: semi-spherical artificial ruby, friction pen with radius (0.25±0.01)mm, tip radius (0.03±0.05)mm, semi-circular arc grinding head without regular friction

Pressure 900g-2000g, 100g increment 1n-20n, 0.5n increment 0-50g, 0-100g, 0-200g5n /10N or agreement value -

Paint, varnish (paint on plastic board during the test), varnish (paint on plastic board during the test), plastic and decorative fabric plastic

Sample size sample size: Max thickness: 12mm

Max400 *100mm(L*W test board: thickness 0.7-1.0mm

Test board: Max thickness: 12mm

Test sample of 400*100mm(L*W) : there is no specific regulation, the plastic length >25mm, the fabric length >50mm(at least larger than the single line distance) test sample: greater than or equal to 50mm*40mm

Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai