Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai

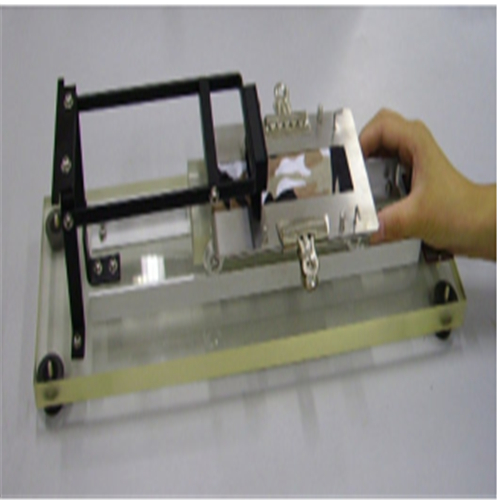

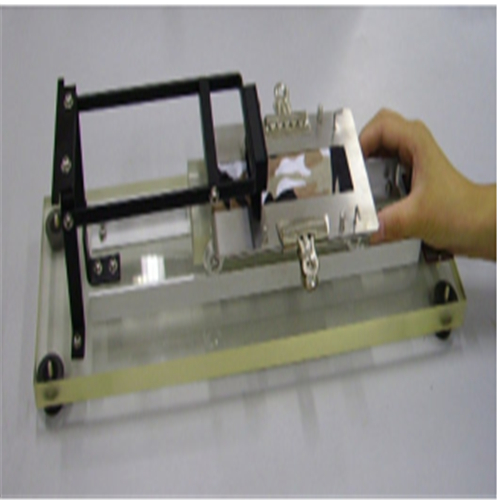

The 45-degree combustion tester is used to measure the combustion performance of textiles. The stainless steel test box is equipped with a glass observation window, which automatically measures the time from the beginning of sample combustion to 0.1s. Ignition time can be set freely. At present, the 45-degree combustion tester is widely used in the textile and material industry, and the frequency is also very high. Therefore, in the long-term use process, the wear and consumption is inevitable, so regular maintenance is necessary.

The principle of

Under specified conditions, the sample is placed at an inclined Angle of 45°, the sample is ignited ls, and the required time for the sample to burn upward with flame for a certain distance is taken as a measure to evaluate the intensity of the textile combustion. For fabrics with surface flexing, the ignition or melting of the undercloth is an additional indicator of the intensity of combustion, but should be noted.

Equipment and materials

Combustion tester

The instrument consists of a ventilated box body, which is equipped with ignition device, sample holder and sample holder (see figure 2), and automatic timer.

A. The inclination of the sample rack is 45°, and the position relative to the flame front can be adjusted according to the thickness of the sample.

B. Gas burner, 4 1/2 syringe needle.

C. Timer can automatically time and accurate to 0.1s.

2. Brush device

Used for sample preparation of fleece or tufted fabric. It consists of a suitable sliding frame for the sample holder and a loaded nylon brush mounted vertically on the sample surface. Four wheels are mounted under the sliding frame, which can move forward and backward in the direction of the sample, a distance slightly longer than the exposed length of the sample. And equipped with a guide rail for sliding wheels to move.

A brush consists of two rows of nylon bristles with diameters of o.41 mm, each with 20 bristles and 4 bristles for every 25mm, with two rows of interleaved bristles. The tuft is flat with a length of 19mm.

B the brush is mounted on a frame, which exerts a pressure of 150g on the sample downward.

C constant temperature oven.

D inner diameter of dryer 250mm.

E marking thread mercerized cotton sewing thread (12tex×3).

F butane (chemically pure).

3. Operating procedures

A take out a sample holder from the dryer, place it on the sample rack in the test instrument, pass the mark line through the guide wire hook of the sample rack flat plate, and then hang a hammer on the mark line just below the guide wire ring to make it taut.

Close the test chamber door. Set the timer to zero, press the start button, and when the timer starts, make the flame contact with the sample surface for 1s. When the flame reaches the marking line hanging on the upper part of the sample, the hammer falls because the line is broken, and the timer stops to accurately record the burning time shown by the chronograph. The time from the sample taken from the dryer to the sample ignited shall not exceed 45s.

C. The combustion condition of the sample should be observed during the test. If the combustion is incomplete, the back of the sample should be observed for signs of carbonization or melting.

4. Any instrument is inseparable from the maintenance, maintenance can not only extend the life of the instrument, but also can make the performance of the instrument not quickly aging and become inaccurate.

1, before use must pay attention to the supply voltage is consistent. When using, the grounding wire of power socket must be grounded according to regulations.

2. When using, do not touch the apparatus and electrical parts with your hands to avoid electric shock.

3. Regularly clean the dust on the surface of the 45-degree combustion tester and inside the box.

4, check the ammeter regularly to see if there is any abnormality.

5. Check regularly whether the fan is running normally and there is no noise.

6. Check regularly whether the vent is blocked and clean up dust.

7. Periodically check whether the temperature controller is accurate. If not, adjust the static compensation of the temperature controller or the sensor correction value.

8. Periodically check whether the heating pipe is abnormal.

9. Check the accuracy of delay device regularly.

10, when the power failure to unplug, to prevent the automatic start of the call.

Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai