Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai

The adhesive buckle fatigue tester is part of the performance test of adhesive buckle. Through a certain number of times of coupling between the coil surface and the hook surface, the shear strength and peeling strength of the meter, the actual use process was simulated to consider its durability.

1.1 test principle

The test principle of

Fix the ring surface and hook surface of the adhesive buckle belt on different roller surfaces. During the test, the roller rolls and the adhesive strap is constantly bonded and peeled. After a certain number of times, it was removed for follow-up test.

Test standard

The adhesive buckle fatigue tester meets the following standards:

1. GB/T 23315

2. DIN 3415

3. The SATRA PM - 123

Technical specifications

1. Roller diameter: the upper (starting)¢162.5mm, and the lower (driving)¢160mm

2. Roller width: 70mm

3. Rolling speed: 60rpm

4. Reversal time: 30s

5. Load: 5kg

6. Counter: LCD LCD display, 0-999999

7. Power supply: AC 220V 50HZ 5A

8. External size: 70×47×60cm

Weight: 51kg

Introduction of instrument

An instrument

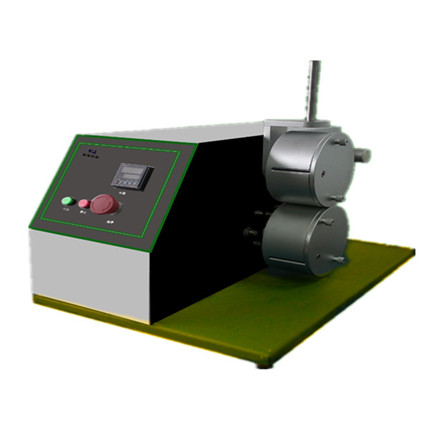

The whole machine is mainly composed of the following parts, as shown in figure 1:

Figure 1. Complete machine diagram

1. Counterweight: it is used with the driven wheel with a pressure of 5kg.

2. Driving wheel: 160mm in diameter, driven by the motor to rotate at a speed of 60rpm, reversing and reversing every 30s. The ring surface is fixed on the driving wheel.

3. Driven wheel: 162.5mm in diameter, driven by the driving wheel. The hook surface is fixed on the driven wheel.

4. Counter: set and display the number of motion cycles.

5. Buttons: including emergency stop button, start button and pause button.

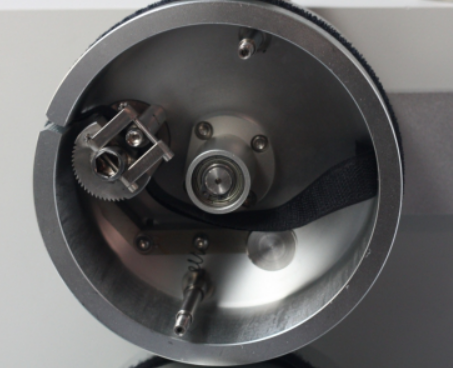

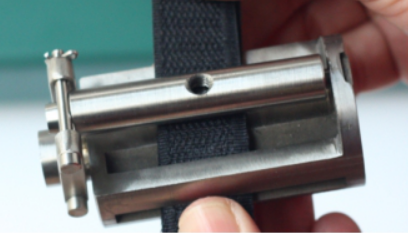

In order to fix the sample firmly, a special clamping device is arranged inside the roller. As shown in FIG. 2 and 3:

FIG. 2. Internal special clamping device

test

Take GB/T 23315 as an example to introduce the test procedure.

Two groups of samples with a length of (540±10)mm and a width not exceeding the groove length were cut from one pair of adhesive buckle belt.

Four sections with a length of (100±5)mm were marked on each section of the hook-surface strip and the coil surface strip, and "1" was marked on one end of each section, and "2" was marked on the other end.

Any group of samples was taken, and the marked ring surface was circled and pasted on the small roller, the hairy surface was back to the roller, and the hook surface was circled and pasted on the large roller, and the hook surface was back to the roller, so that the sample and the roller were parallel and consistent. Ensure that the specimen is glued to the entire effective width after the roller is rotated.

Adjust the counter and run the test device to remove the sample after 1000 or 3000 times of sample clutch.

The samples were cut into 4 sections along the marking line, and the shear strength of 4 groups of samples was measured. The arithmetic mean value of the measured results of 4 groups was the shear strength after 1000 or 3000 times of clutch of the adhesive buckle.

The second group of samples was taken for another test.

The samples were cut into 4 sections along the marking line, and the peel strength of 4 groups of samples was measured. The arithmetic mean value of the test results of the four groups was calculated as the peel strength after 1000 or 3000 clutch times of the adhesive buckle.

Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai