Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai

Introduction of scratch resistance tester

Its application fields include rigid organic materials, coating adhesives, powder coatings, anodized materials, soft metals, plastics and glass, etc. It can also be used to test the quality of adhesives of the same materials and protective coatings and the limit performance of similar materials. The instrument is composed of balance bar, fixed weight, adjusting weight, sample carrying disk, etc. Before the test, the height of the balance bar should be adjusted according to the thickness of the sample, so that the scraping head is installed in the middle of the balance bar, and the sample is installed after the sample carrying disk, so that the balance bar can be kept horizontal. During the test, the fixed weight is not moved, and the moving adjustment weight controls the weight pressed on the sample. With the counterclockwise rotation of the sample carrying disk, the scraping head leaves an arc mark on the sample surface.

1.1 test standards

The scratch resistance tester meets the following standards:

LAS/NZS AS2924.2

LASTM C217

438.2 lBS EN

LBS EN 13310

LBS EN 14323

LDIN 68861-4

LDIN 53799

1.2 test principle

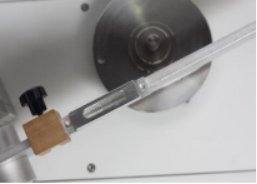

Place the sample in the groove of the thickness control device and adjust the nut position. Install the sample on a rotatable circular platform, and fix it with a pressing block and nut. Install the scraping head into the groove corresponding to the middle of the scale rod. Rotate the balance bar so that the scraping head is in contact with the sample. Start the instrument, the disk moves, and the scratch head leaves a scratch on the sample surface.

1.3 instrument structure and function

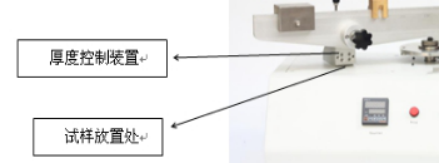

Balance bar adjusting parts: this part includes thickness control device, height adjusting nut, front and back position adjusting nut, balance bar composition. The height of the balance bar is determined by the thickness of the sample. Before the test, insert the sample into the groove of the thickness control device, and adjust the nut by adjusting the height so that the sample is just stuck in the groove. When the sample is installed on the circular sample carrying platform and the friction head is loaded into the balance bar, the head supports the sample. At this time, the balance bar is basically parallel and only needs to be fine-tuned (the horizontal bubble is placed to see whether it is horizontal or not).

Part of the standard requires that the test results are concentric circles of different radii, adjust the front and rear position control nut to control the scraping head and sample load

The distance from the center of the disk, resulting in indentations of different radii.

Pressure regulating parts: this part includes fixed weights, moving weights and balance bars. The balance bar is marked with a scale of 0-500, with each grid representing 10g of pressure. When in use, the middle cut of the moving weight is aligned with the upper scale line of the balance, and the pressure applied on the surface of the sample is the pressure shown in the cut line.

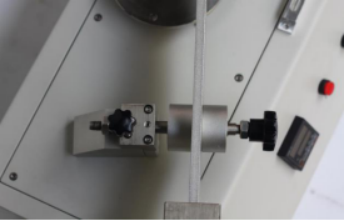

Sample loading part: this part is composed of sample loading disk, fixed plate and fixed nut. Place the sample on the sample carrying disk and then press it with a fixed piece, and then fix it with a nut.

Control parts: including counter, start button, pause button and power switch composition.

Test steps

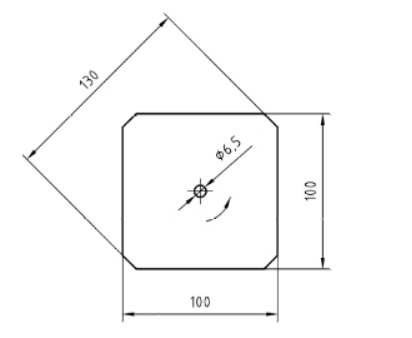

Sample preparation: the standard sample is a square piece with the size of 100mm*100mm, with edges and corners on all sides and an opening with a diameter of 6.5 in the middle, as shown in the figure below:

Place the sample at the thickness control device and adjust the upper end bolt so that the upper surface of the sample contacts the lower surface of the thickness control device.

Remove the sample, place it on the test plate, tighten the nut on the sample, lower the balance bar, and place the horizontal bubble on the balance bar to see whether the balance bar is horizontal. If there is no level, adjust the rear bolt to make the bubble level.

Move the right end weight to the required pressure position, tighten the bolt at the back end of the weight so that it does not move during operation.

Power on, select the running cycle number of the experiment, and press the start button to conduct the experiment.

Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai