Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai

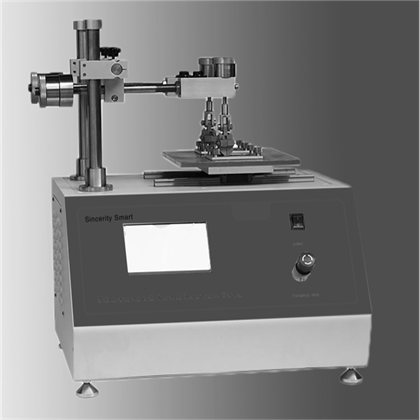

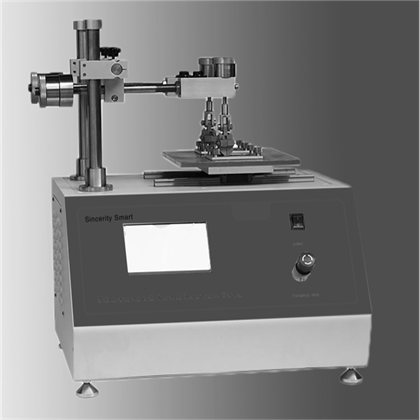

Watch abrasion tester. Watch wear tester

Wear tester for watches

To test the scratch and wear resistance of watches, clocks, glasses, etc. LCD control and display the test process, can be set according to user requirements reciprocating wear times, motion travel, reciprocating speed and other parameters. Unique friction arm design, the realization of different friction head replacement. The implementation of precise pressure control according to lever balance principle. Fully meet the different requirements of different standards for friction form, friction head, pressure, etc

Testing principles;

The test sample is held on a horizontal bench and worn down as it moves horizontally with the specified abrasives and loads. The other end of the test arm is equipped with a weight to maintain the balance of the test arm to ensure the accuracy of the sample surface load. The height of abrasive and load rack can be adjusted to suit the test of samples of different heights

Technical specifications

Travel range: 6-150mm adjustable

Speed range: 1-100 reciprocating /min stepless adjustable

LCD control, can set the speed, the number of reciprocating motion and other parameters

LCD displays and controls the test status in real time

Two station design, saving time of test

Can meet various standard requirements, according to the needs of users with weights and friction head

Weight: 48.5 kg

Size: 532*471*630 (W*D*H)

Power supply: 220V, 50HZ, 3

optional

Host 1

Test software set 1

2 sets of test arm kits

6 weights (1N,2N, 3.5n,5N,10N,24N)

2 grinding heads of D42 1775 (R18, 40mm long)

2 grinding heads of cs-10

H-18 grinding head 2

2 sets of sample fixing frame

1 the brush

1 pack (20 pieces)

1 power cord

1 manual

Balance adjustment

Including sample clamping, lever balance adjustment and so on

The sample is fixed on the test platform with a fixture.

Tighten the retaining knob to keep the lever level. The friction head approaches but does not touch the specimen.

Turn on the power switch and click into the test interface. The start and end positions of the test platform can be known through the reset key, so as to determine the position of the friction head. Fix the front and rear position of the balance bar and tighten the knob.

Loosen the locking knob, and the balance bar may tilt due to weight imbalance. Adjust the front and rear position of the weights until the balance bar is balanced.

Adjust the position of the friction head to make it contact with the sample.

Add the additional weight to the friction head. The weight pressed on the sample is the weight of the additional weight.

Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai