Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai

This instrument is suitable for various automotive interior materials, such as plastics, rubber, leather, fabric, coating materials, non-coating materials and other composite materials, etc. Scratch-resistant instrument is applicable to various kinds of automobile interior material scratch-resistant performance test instrument, instrument integration of three domestic test standards (five finger scratch-resistant method, 100 grid method, plastic scratch-resistant method). This test method is used to test the ability of surface material to resist damage caused by scratch. According to the nails or other hard objects that may be contacted in the use of materials, the scraping fingers of different materials shall be applied to the surface of samples under certain pressure in accordance with the specified direction, stroke and speed. The scraping head and samples shall move relatively, generating one-way and non-reciprocating linear scraping track, and the scratches shall be parallel to each other. Zui finally evaluates the material's scratch sensory grade, the color difference between the scraped and unscraped areas, or the zui minor scratch force when the sample surface is damaged

Principle of scraping:

This multi-functional wear tester meets the following standards:

GM 14688 (A)

GM 14688 (B)

PV 3951

GB/T 9286-97 / ISO 2409 iso2409

GB/T 9279-2007 / ISO 1518:1992

Instrument features:

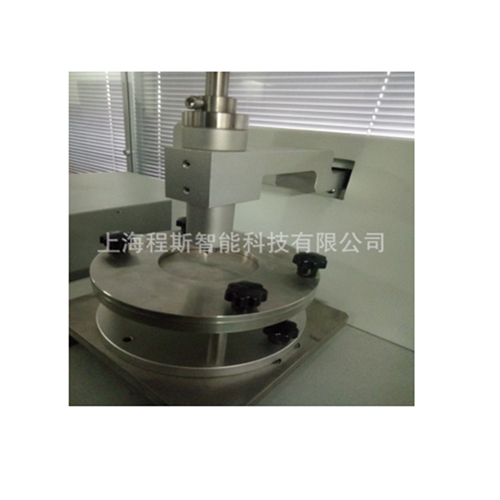

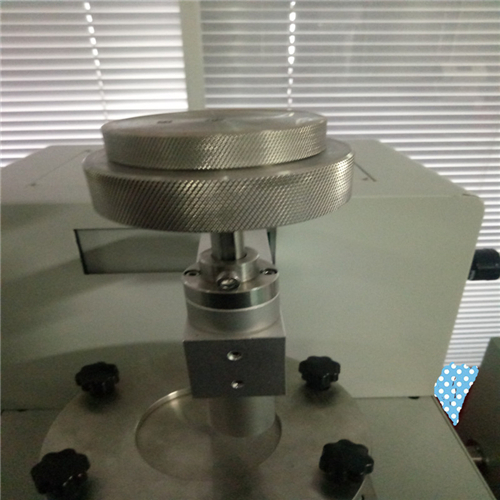

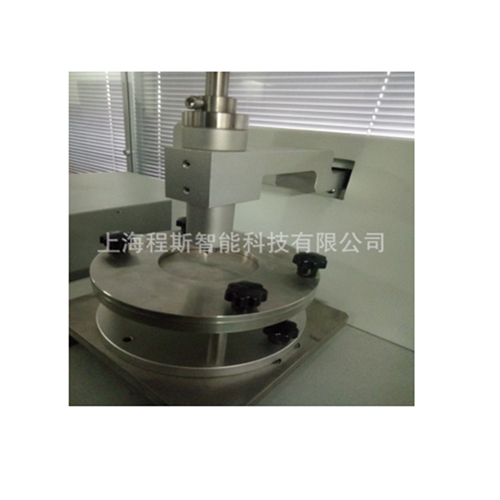

1. The instrument is composed of motor drive mechanism, scraping component, sample clamping fixing device, etc.

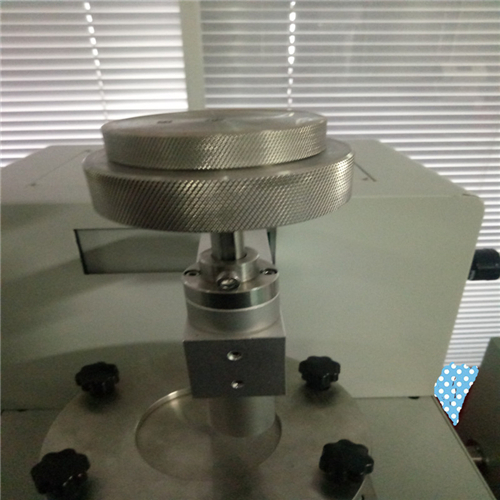

2. The scraping components include scraping bracket, scraping finger, scraping designated position sleeve, pressurizing device (weight and weight support bar), etc.

3. The instrument can be freely installed, replaced and disassembled with different specifications of scraping fingers, and can carry out uniform unidirectional linear scraping movement under different loads.

4. The embedded system and man-machine interface operation are adopted for automatic control of the test process, and the precise servo motor and ball screw drive play a decisive role in the control of scraping speed under relevant standards.

5. Use tungsten carbide as scratch finger to increase the service life of the instrument.

6. Aluminum alloy and stainless steel, simple, light and corrosion resistant.

Technical parameters:

1. Travel range: 10-200mm;

2. Speed range: 10-200mm/s;

3. Speed buffer: 10±1mm;

4. Diameter of metal scraping head: 0.5mm, 0.75mm, 1mm(Erichsen318), 3mm, 5mm, 7mm;

5. Metal scratch head material: tungsten carbide, sapphire, hard alloy;

6. Total weight of pressurized weight and scraping component: 5N, 10N, 15N, (optional and customized) the quality error shall not exceed 1%;

Plastic fingers: polymethyl methacrylate (PMMA);

I. diameter 16mm and thickness 1mm;

Ii. The radius of the scraping edge is 0.5mm;

Iii. Shore D85 hardness.

8. Power supply: AC220V±10%, 50Hz.

The instrument can meet various test standards, and can customize the motion travel, speed and reciprocating period of the test platform according to customer requirements.

The test principle of

Bagel scraping test: the purpose of the test is to test the resistance of paint to mark shedding. The common bagel method is manual test, which takes time and effort to operate. The instrument is driven by two motors to control the length of scratches and the distance between scratches. Movement process as follows: the first stage of yi test, reciprocating mobile platform movement (half a circle) at a time, cylinder scraping refers to lift, the motor drives the scratches refers to the longitudinal mobile distance, cylinder scraping refers to put down, and then moving platform movement (half a circle) at a time, cylinder scraping refers to lift, motor drive the scraping refers to the longitudinal mobile distance again, and again. After marking the specified number of bars, manually rotate the test board 90 degrees to complete the second phase of the test. The instrument can achieve the spacing of grid 2.0mm, meet the requirements of the standard.

FIG. 1. Detail diagram of the layout when the scratch spacing is 2mm

Test standard

Configuration:

1. Test module: bagel method scraping (or cross grid, hereinafter collectively referred to as bagel method scraping) mode

2. Reciprocating moving platform moving distance: 10-200mm adjustable

3. Reciprocating moving platform moving speed: 10-200mm/s adjustable

4. Movement distance of scraping finger: 0.5mm, 1mm, 2mm adjustable

5. Scraping test load: 5, 10n, 15N

6. Cylinder controls the falling and lifting of bagel scraping finger

7. Power supply: AC 220V 50HZ

8. External specification: 662mm*360mm*657mm(W*D*H)

9. Weight: 75kg

Bagel method scraping sleeve: the scraping finger is installed in the installation hole, which can be fixed or free falling on the top of the sample.

Attention should be paid to the installation of the scraping finger of the bagel method: the fixed shaft sleeve should be installed 2-3mm above the support arm, so that the scraping finger and the upper weight will be added to the sample during the test.

Mobile platform fixture: the fixture is equipped with four movable positions and a large splint. The specimen is firmly fixed without slippage

100 grid method scraping fixture: by unscrewing the fixing screw, manually rotate the scraping fixture 90°, tighten the fixing screw to fix the current position.

PLC liquid crystal display screen: control and display test parameters and test process.

Emergency stop button: press the emergency stop button immediately when an abnormal condition occurs.

Note: the test speed is generally required by the standard. If the speed is too high and the travel time is too small, the damage of the instrument may be easily caused.

Shanghai chengsi intelligent technology co., LTD

Contact: Mr. Gao

Phone: 17701637746

Phone: 19821311892

Address: no. 265, east street, zhuangxing town, fengxian district, Shanghai